Cylinder Liner

The Cylinder Liner is integral to the engine block, and is one of the critical functional parts that forms the combustion chamber.

To be compatible with various engine block types, our main product line-up is formed of cast-in liners, thin-wall-dry liners and wet liners.

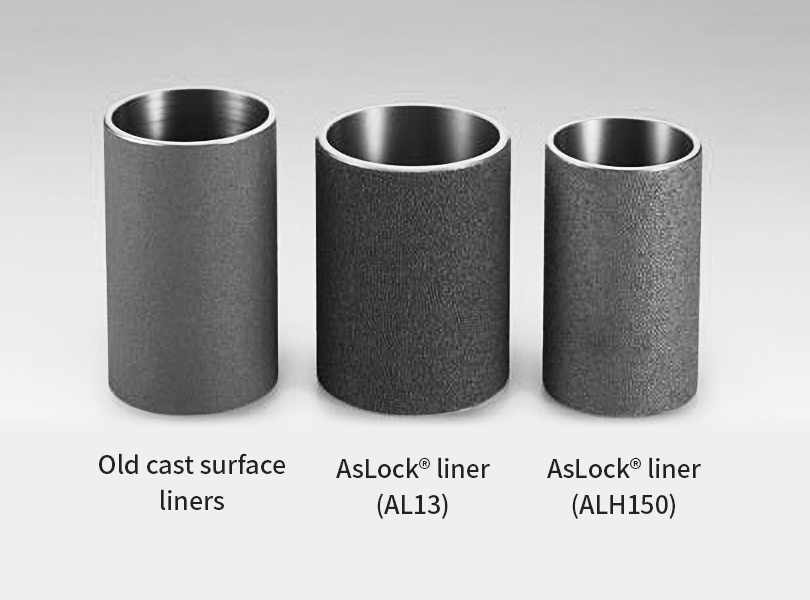

Cast-in liners - patented technology

Characteristics

- Integral structure through simultaneous casting with aluminum engine block.

- Through the centrifugal casting method, it can be manufactured at low cost.

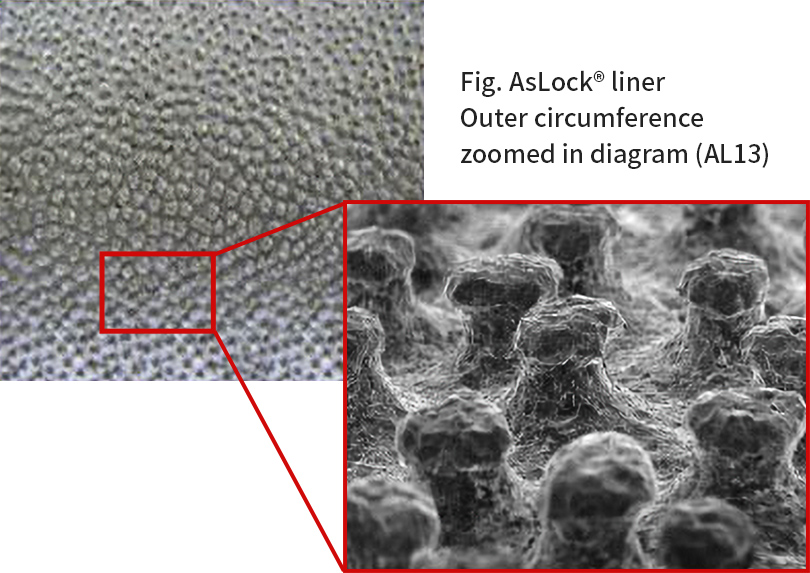

- The AsLock® liner has bundled protrusions on the outer circumference, improving adhesion compared to old cast-in liners.

- The AsLock® liner has 2 types, AL13 and ALH150. Compared to AL13, ALH150's protrusions are lower, with high protrusion density, giving the improvements of bore pitch shrinkage and heat conductivity from liner to engine block. As a result, ALH150 is effective in the shift to small, high-output engines.

Examples in use

Gasoline, diesel engine (aluminum engine block)

Thin-wall-dry liner

Characteristics

- This is a pressured type of Cylinder Liner, the outer circumference contacts the engine block and has no direct contact with cooling water.

- As it is thin-walled, the spacing between cylinders can be smaller, enabling a smaller, lighter engine.

- A phosphate film is possible to improve burn resistance.

Examples in use

Medium/large diesel engine

Thin-wall-dry liner (nitride specification)

Characteristics

- This is a pressured type of Cylinder Liner, the outer circumference contacts the engine block and has no direct contact with cooling water.

- As it is thin-walled, the spacing between cylinders can be smaller, enabling a smaller, lighter engine.

- Nitride specification to improve friction resistance.

Examples in use

Medium/large diesel engine

Wet liner

Characteristics

- This is a pressured type of Cylinder Liner, the outer circumference forms part of the water jacket.

- To prevent cavitation, it is possible to chrome plate or give some other coating to the outer circumference.

Examples in use

Medium/large diesel engine